Dimensions & Length

Creek Plastics conduit meet’s the dimensional specifications recommended by the American Pipe Institute and ASTM Standards.

Standard length tolerances will be held at +/-5% of the ordered lengths.

The specs for the sizing and wall thickness vary depending on the type of Conduit or pipe you are using. The specific specifications can be found in the following charts.

Telecommunications F-2160

| ASTM TEST | Description | |

|---|---|---|

| D-1505 | Density g/cm3 | 0.941 – 0.955 |

| D-1238 | Melt Index, g/10 min Con 190/ 2.16 | .05 – .4 |

| D-638 | Tensile Strength at Yield (psi) | 3000 – <4000 |

| D-1693 | ESCR Condition B F20 | > 192 hours |

| D-790 | Flexural Modulus, Mpa (psi) | 80,000 – <160,000 |

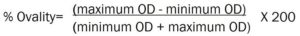

Tolerances for Ovality on conduit are based on a percentage. Use a Vernier caliper or a micrometer to measure and note the largest and smallest diameter. Use those two numbers to complete the following formula.

Maximum allowable ovality of ½”-2” conduit should not exceed 7%. Over 2” and including 3” has a Maximum allowable ovality of not more than 10 %. Due to shipping limitations and associated coil requirements ovality for 4” and larger conduit may exceed 10%, it is recommended that rerounding/straightening equipment be used to install coiled conduit in 4” and larger diameters.